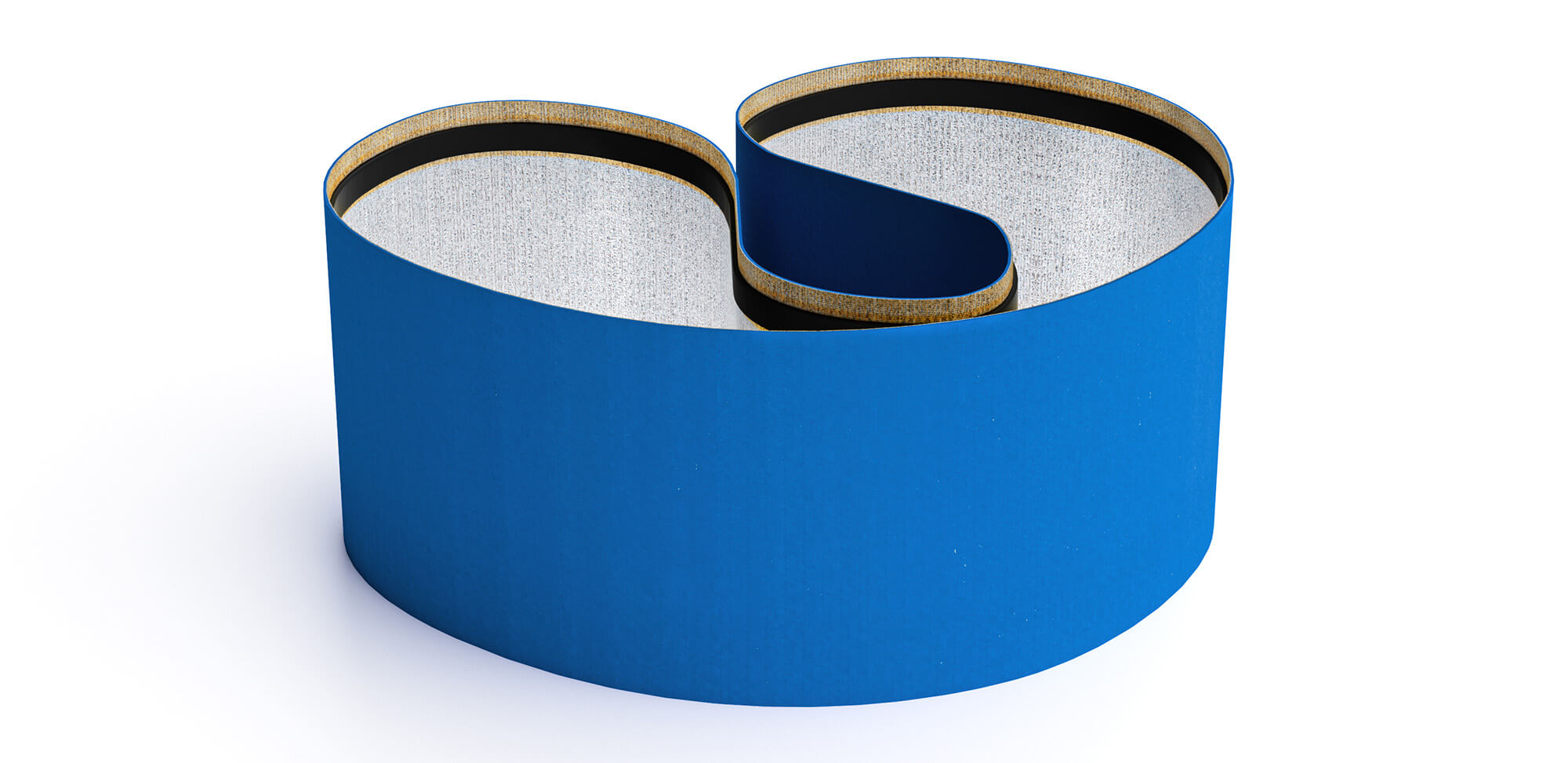

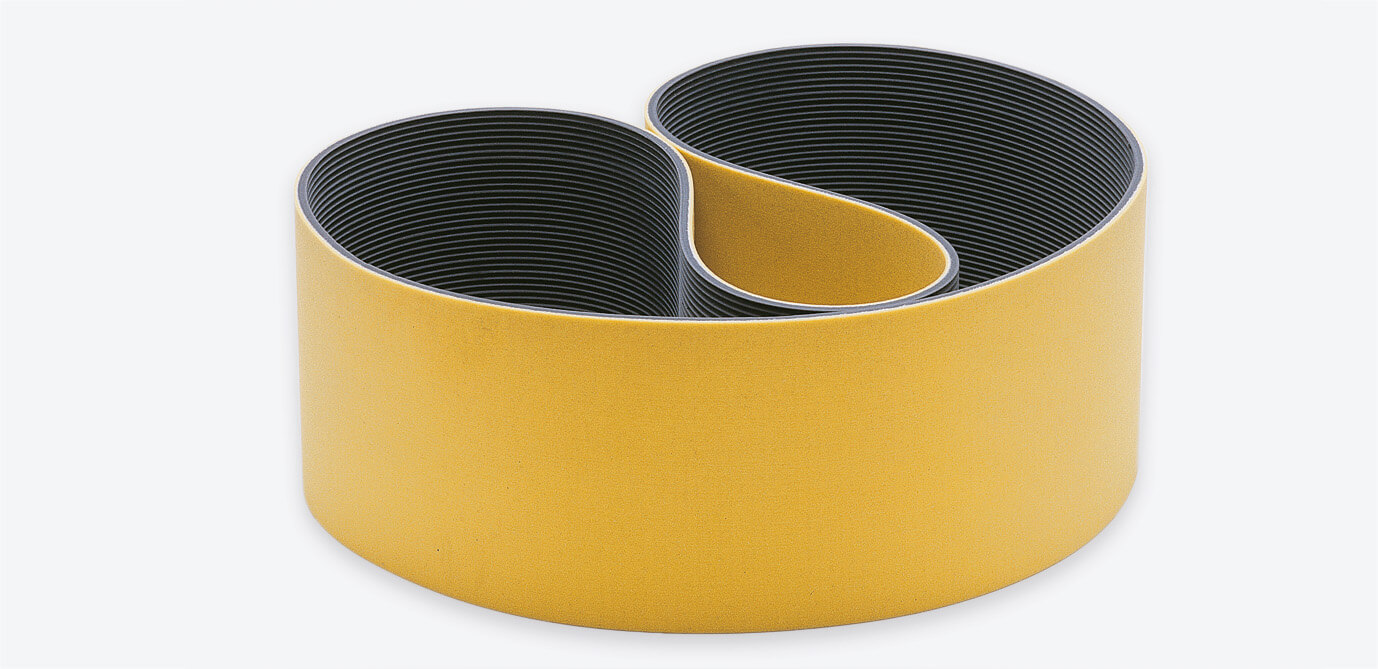

Vacuum Timing Belt (VFFS)

The Vacuum Timing Belt (VFFS) is a special timing belt for our customers’ specific production requirements. For many years the Max Schlatterer GmbH & Co. KG has been and still is a reliable partner of well-known OEMs of the packaging industry. Additionally a significant number of distributors and end-users worldwide rely on the Esband quality. We can not only offer current market versions of the VFFS belt but also specially made solutions in accordance with customer requirements.

UNIQUE CHARACTERISTICS

- High functional reliability due to a high and consistent coefficient of friction

- High service life due to high wear resistance

- Individual solutions possible by choice of different materials and almost unlimited special fabrications

- FDA approval possible

Areas of Application

Questionnaires

Let us get to know you by filling in our questionnaire. The more we know about your requirements, the more precise our solution for you may be. Click here to download the form.

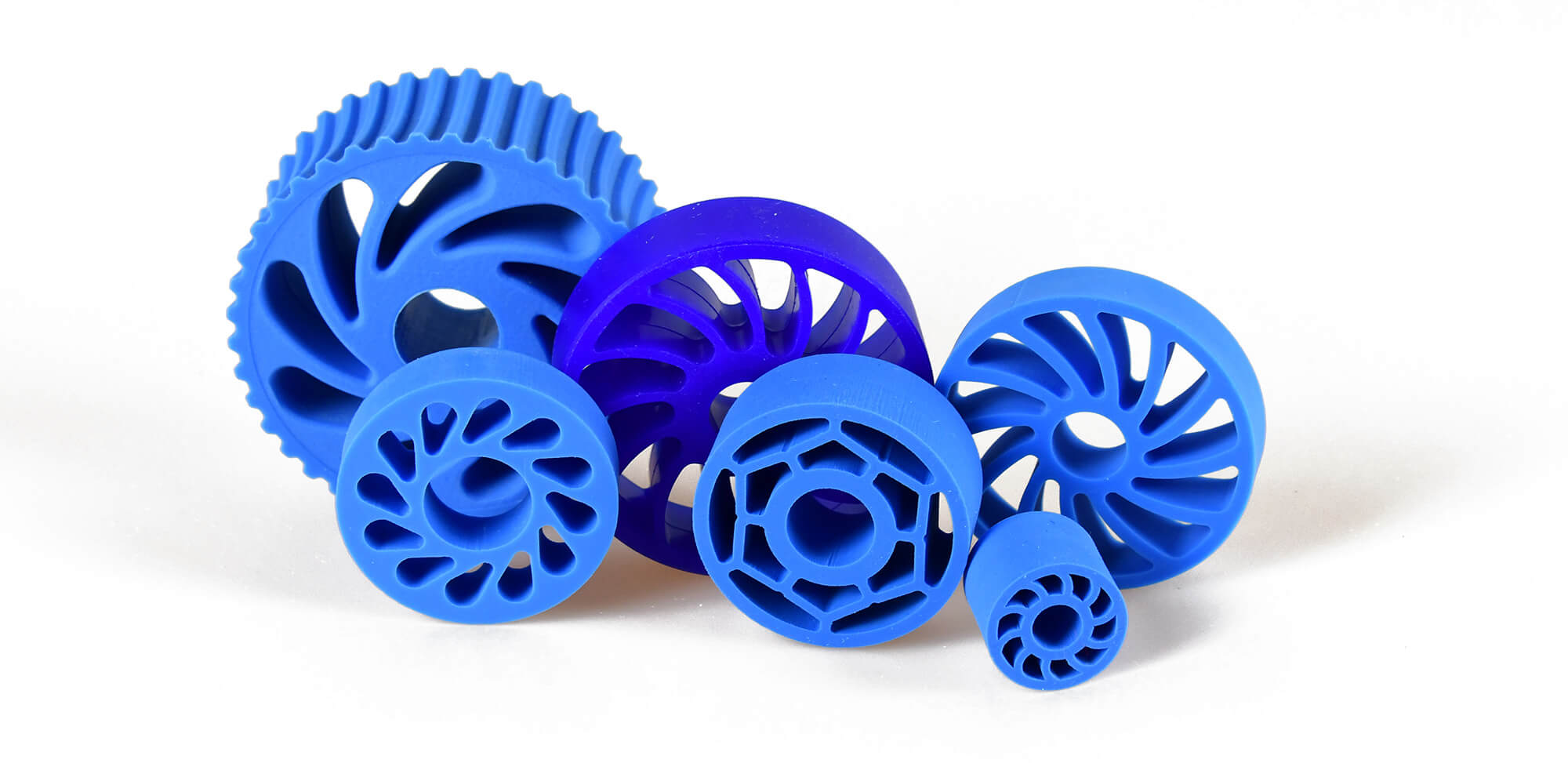

Related Products

For more information please contact us.