TOBACCO INDUSTRY

Tapes: We know how!

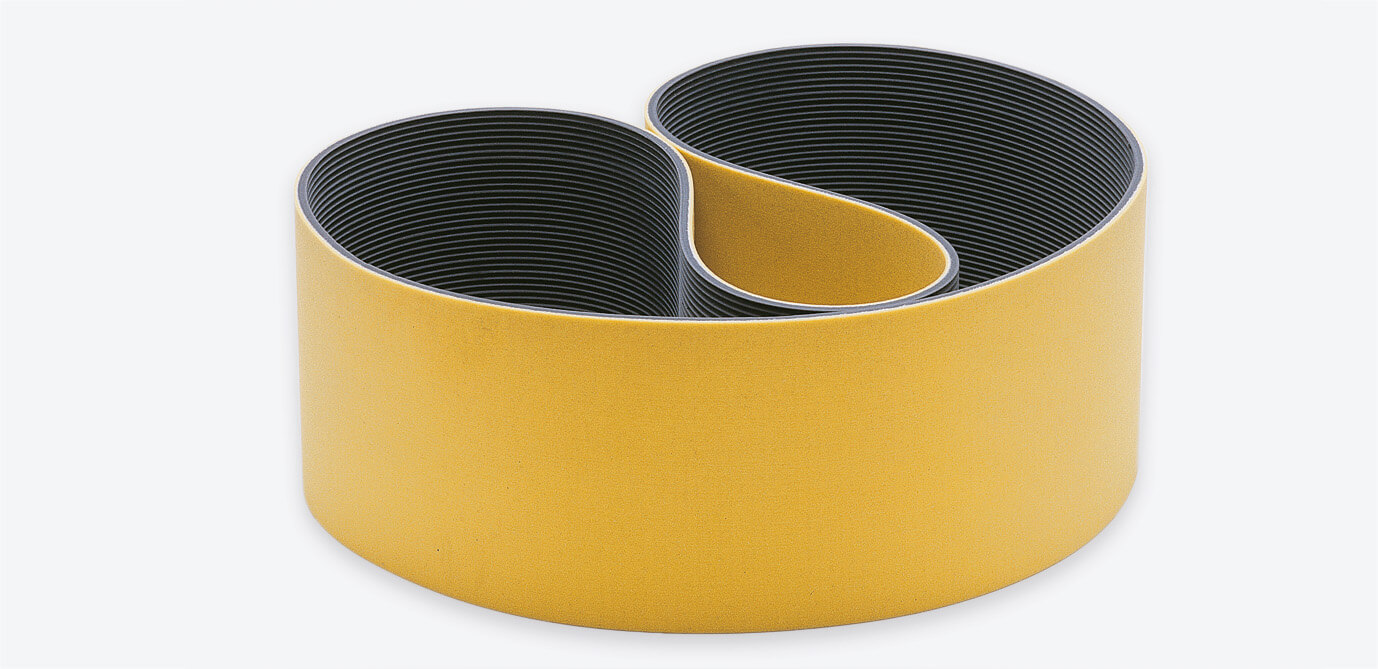

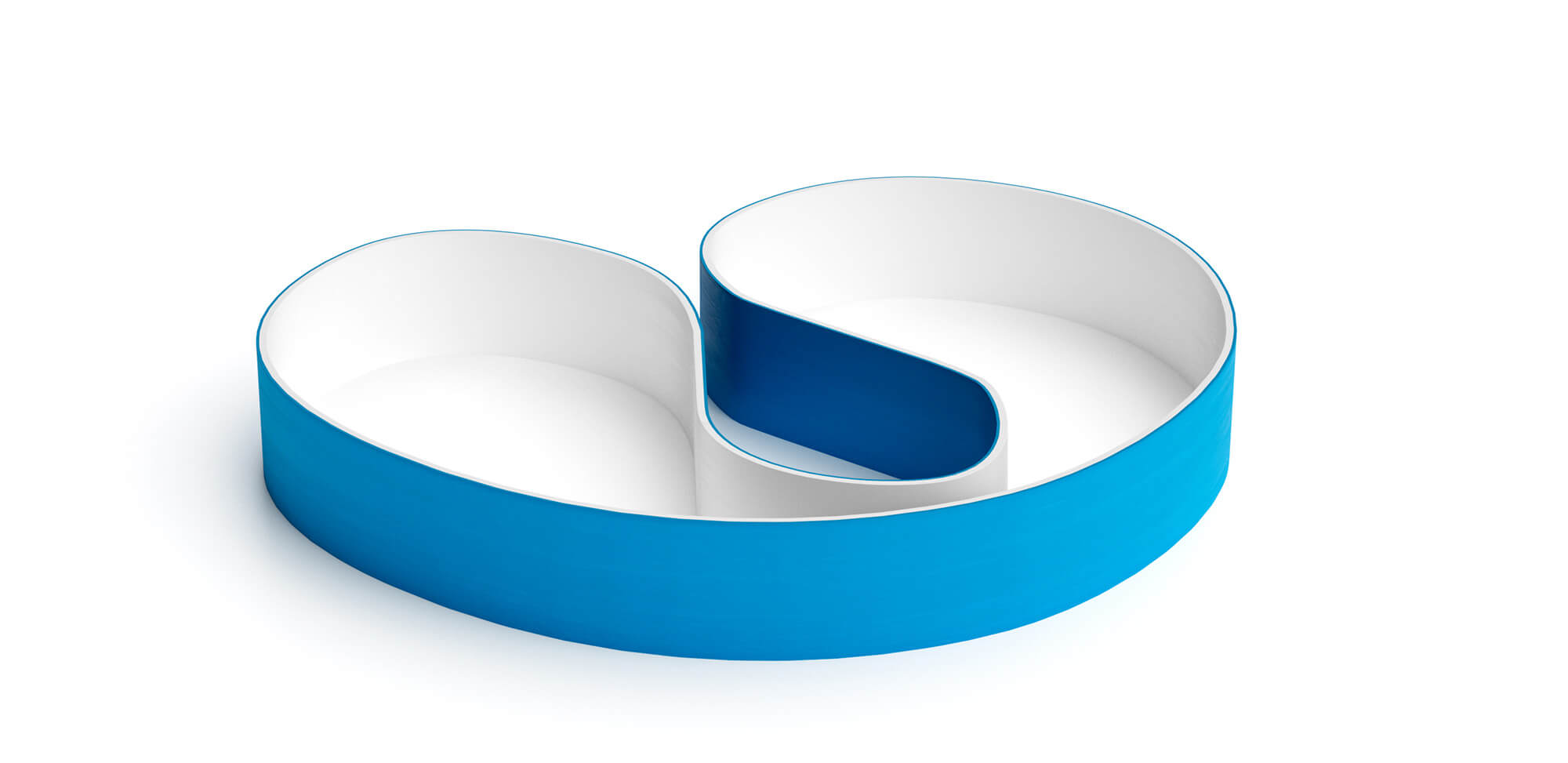

The quality of our tobacco belts – garniture and suction tapes – is the result of the interaction of several elements. It already begins with the quality of the raw material. As the global market leader, we are aware of our special responsibility and manufacture our garniture tapes from natural fibers, chemical fibers or blended fibers. We produce our tapes depending on your requirements.

We also supply the industry with drum tires, tobacco return conveyors as well as conveyor and drive belts.