PAPER INDUSTRY

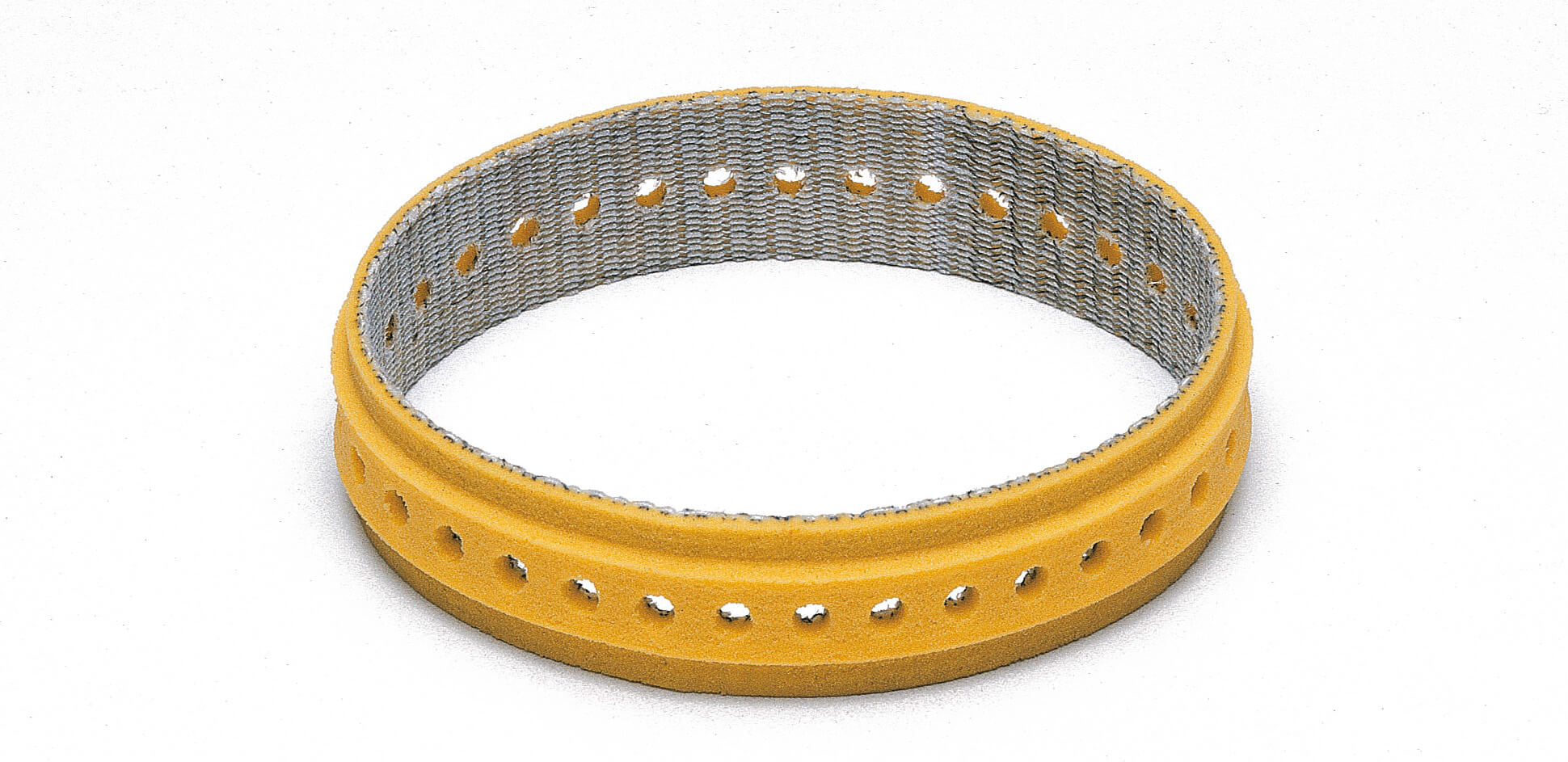

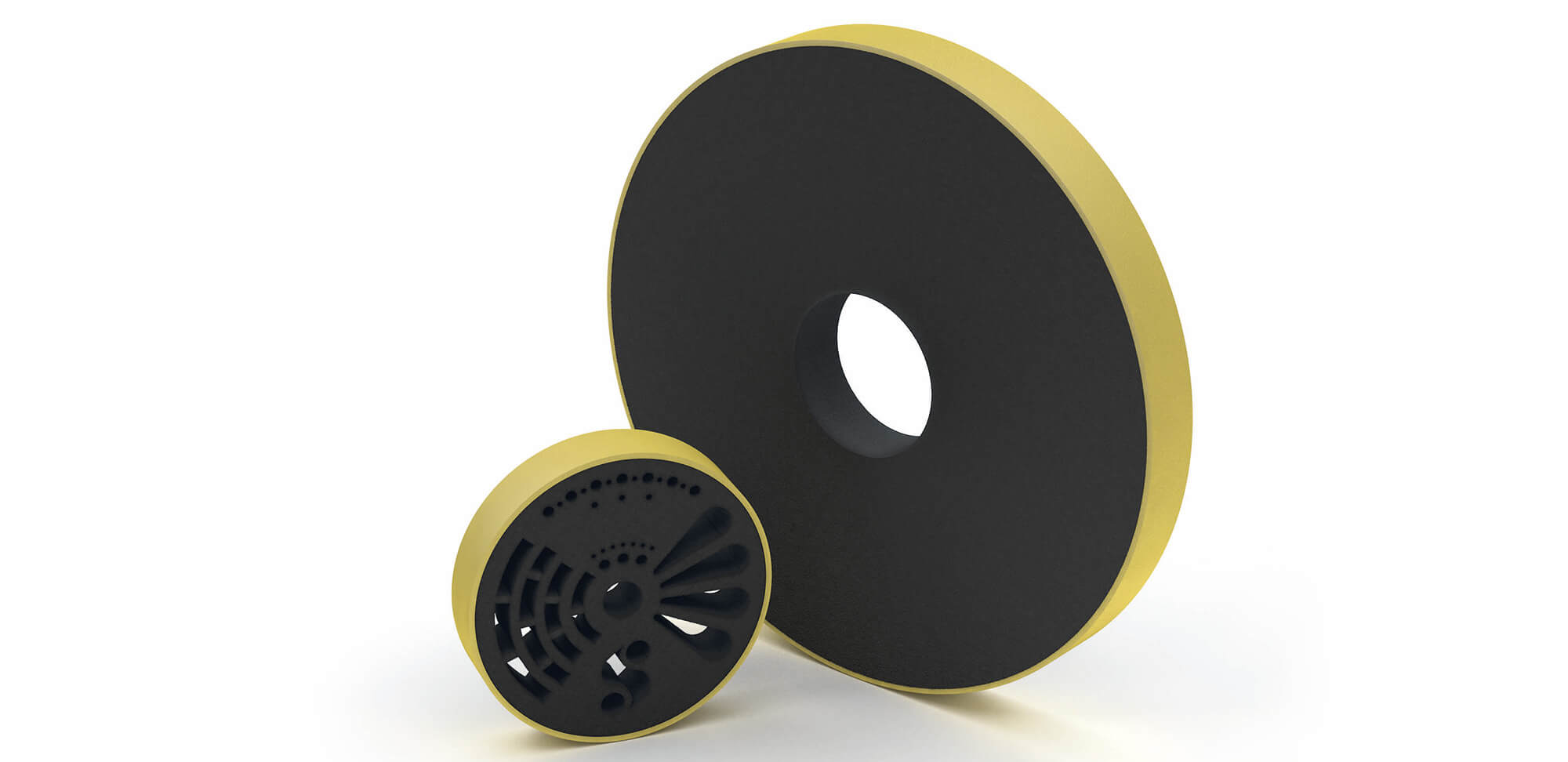

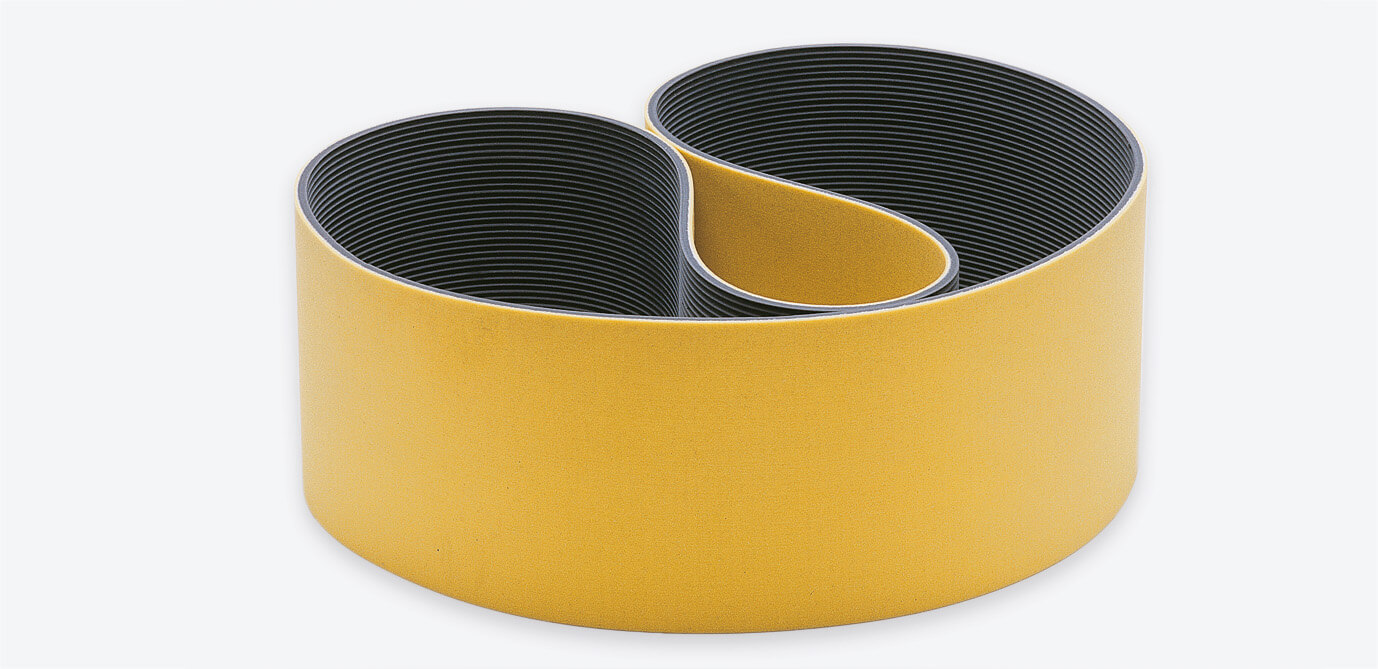

Belts and more in proven Esband-quality

The printing and paper industry has demanding operating conditions like high running speeds. This makes a precise handling of special process belts necessary. Those special conditions also require a homogeneous belt structure and highest flexibility. For these challenges our endless Esband belts offer a customized solution for every stage of printing and further paper processing.